Eco-Friendly Energy-Saving Grease

Greases are used on automotive parts and in many types of industrial equipment, and are key to the smooth operation of bearings. It's no exaggeration to say that without grease, our machines would stop moving.

People's growing concern over global carbon reduction and/or decarbonization has created a need for greases with energy-saving effects.

Concept of Energy-saving Grease

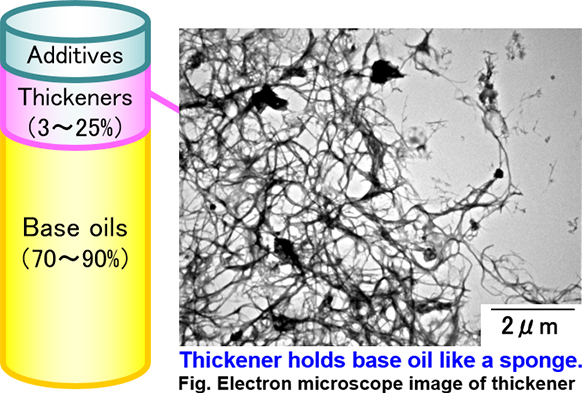

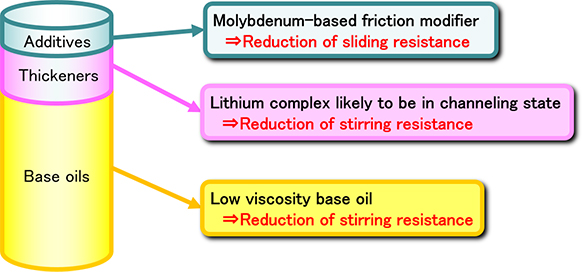

Grease consists of three major components: base oil, additives, and thickener. Thickener forms entangled fiber network which can be observed using an electron microscope. Due to the network structure of thickener, thickener holds base oil like a sponge. In order to develop energy-saving grease, optimization of the formulation of these three components is necessary.

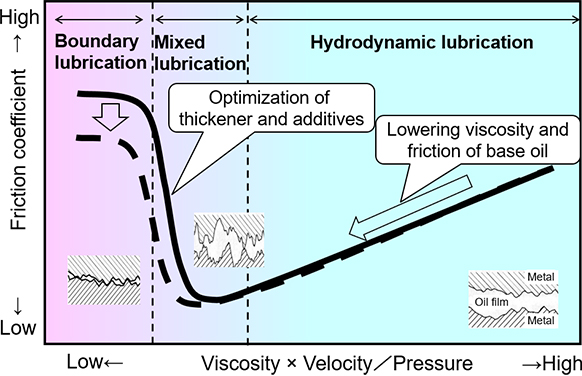

The design of energy-saving grease is as follows.

Energy-saving can be achieved by reducing friction. The Stribeck curve shows the relationship between the lubrication states and friction coefficient. In the hydrodynamic lubrication region where the oil film prevents metal contacts, it is important to reduce stirring resistance by selecting low viscosity and low friction base oil. In the boundary and the mixed lubrication regions, where the oil film is broken and metal contact occurs, it is important to reduce friction and wear by optimization of thickener and additives.

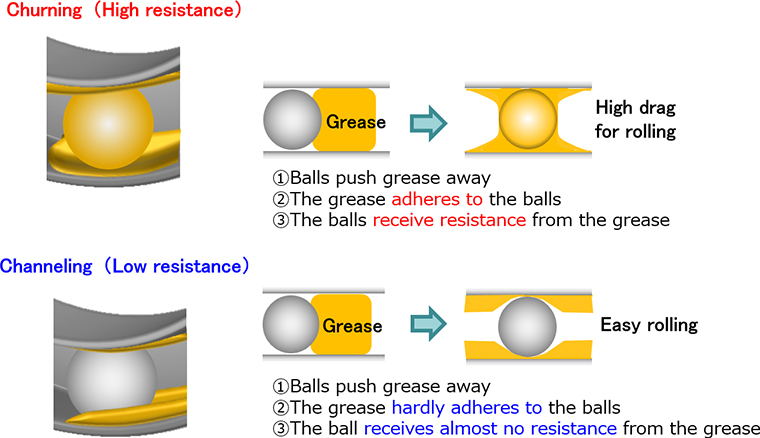

It is necessary to consider difference in rotational resistance of bearings due to the state of grease distribution. As shown in the figure, when balls pass through grease inside the bearing, grease is pushed away. In the churning state, the grease adheres to the bearing balls after the balls pass through, therefore the resistance that balls receive from the grease increases. On the other hand, in the channeling state, the grease hardly adheres to the balls, so the resistance becomes small. For energy-saving grease, a proper transition to the channeling state is desired, and to achieve this, the grease must have the property that stays in appropriate places.

Concept based on flow characteristics specific to grease (flow in rolling bearings)

Grease Fluidity

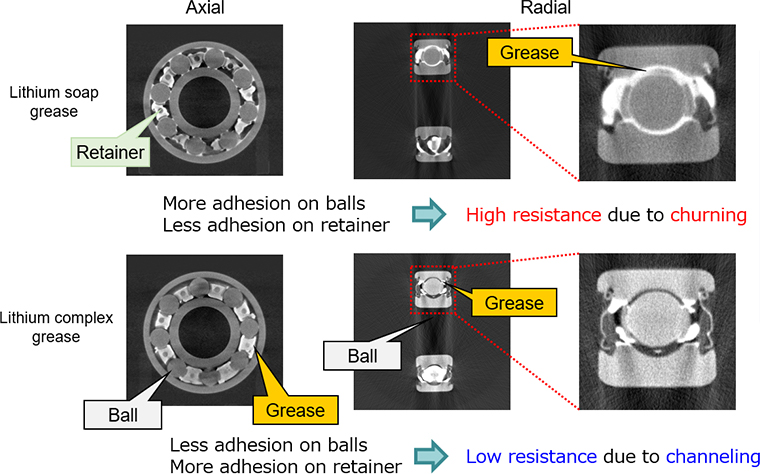

In general, lithium complex grease has stronger fibers than lithium soap grease, and has flow characteristics that allow it to stay in place, so it is likely to get into a channeling state.

We have succeeded in observing this phenomenon in three dimensions by using neutrons.

Since neutrons easily penetrate metals and are absorbed by grease, it is possible to visualize the flow state of the grease in metal bearings. In the case of lithium soap grease, it can be seen that there is a large amount of adhesion to the balls in the bearing, resulting in a churning state, and therefore, stirring resistance is high (top figure). On the other hand, in the case of lithium complex grease, there is little adhesion to the balls and the grease is in a channeling state, indicating that the stirring resistance remains at a low level (bottom figure).

In recognition of this achievement, our company received the award, Hamon President Choice, from the Japanese Society for Neutron Science.

"Observation of grease fluidity in a ball bearing using neutron imaging technique," JAST Tribology Conference, Beppu, November 2020, E16

J-PARC MLF BL22(RADEN), General use proposal number: 2019B0229

Neutron Imaging for Observation of Grease Fluidity in Ball Bearings, Hamon, Vol.31, No.4, 2021, 162-165

Development of Energy-saving Grease "TOUGHLIX MP2"

We have developed the grease “TOUGHLIX GREASE MP2" (hereinafter referred to as "TOUGHLIX MP2") that achieves energy-saving performance by optimizing the three major components of the grease.

For base oil, low viscosity base oil was applied to reduce stirring resistance; for the thickener, a lithium complex was selected, which can reduce stirring resistance due to channeling state; for the additives, a molybdenum-based friction modifier was chosen to reduce sliding resistance.

Energy-saving Performance of TOUGHLIX MP2

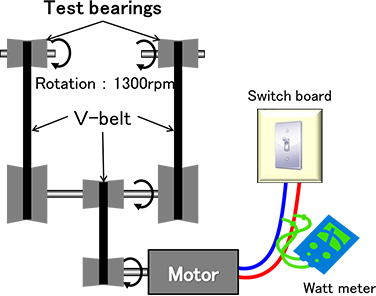

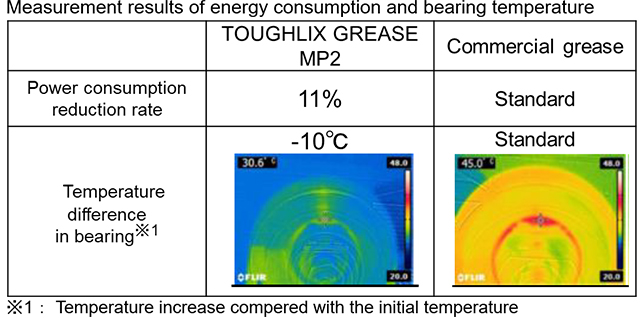

Using the test equipment shown in the figure, experiments were conducted to measure electricity consumption of the motor and temperature inside the bearing. It was shown that the electricity consumption was reduced by up to 11%, and that the temperature rise of the bearing was suppressed by up to 10°C. These results are extremely superior in terms of energy-saving.

Application of Energy-saving Grease

TOUGHLIX MP2 can be applied to a wide variety of equipment as shown in the table. It can improve the operating efficiency by saving energy and reducing power consumption. In addition, it can reduce the time and effort required for maintenance work on various machines and vehicles by extending the service life of bearings through suppression of temperature rise.

TOUGHLIX MP2 is a multi-purpose grease with all superior performances such as extreme pressure, heat resistance, water resistance, and long life.

Click here for product introduction

| Lubricated parts | ||

|---|---|---|

| Application | Construction machinery Agricultural machinery |

Engine peripherals, Wheels, Propeller shafts, Dampers, Swivels, Pedals, etc. |

| Rail road | Axle, Main electric motor, etc. | |

| Industrial machinery | Rolling mill, Continuous casting equipment, Sintering equipment, Pallet carts, Cranes, Unloading equipment, etc. | |

| Machine tool, Electric motor, Linear motion device, Reduction gear, Vacuum pump, Compressor, Chain, Robot, Fan, etc. | ||

| Home appliance | Vacuum cleaner, washing machine, air conditioner, ventilator, copier, etc. | |