Development of Next-Generation Engine Oils

Research and Development for Ultra-Low Viscosity Engine Oils

The pressing need to reduce CO2 emissions from automobiles has created a need for engine oils with much better fuel-saving performance. One effective means of improving fuel-saving performance is to lower the viscosity of the engine oil. The list of SAE viscosity grades now includes lower viscosity grades (Fig. 1), and a growing number of automobiles are able to use low viscosity engine oils. Japan is one country where the shift toward lower viscosity engine oils started earlier than in many others.

Looking ahead to the next generation, we're currently working on development of ultra-low viscosity engine oils with even greater fuel-saving performance. A critical piece of the puzzle for creating such an engine oil is a high viscosity index (VI). Figure 2 shows the relationship between temperature and viscosity in an engine oil. As you can see, the engine oil is more viscous at lower temperatures, which increases drag inside the engine. An oil with a high viscosity index will have a lower viscosity at low temperatures, which translates to higher fuel-saving performance. The primary component of any engine oil is the base oil. To create an ultra-low viscosity engine oil with a high viscosity index, it is critical to use a base oil with a high viscosity index. Using WBASE, an ultra-high VI base oil technology developed in our own labs, we're working to develop high-VI, ultra-low viscosity engine oils with outstanding fuel-saving performance. (Fig. 2)

Development of low friction engine oils

For an engine oil to have good fuel-saving properties, it must have a low viscosity and reduce friction between parts in sliding contact in the engine.

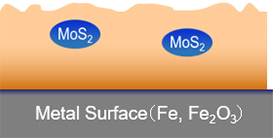

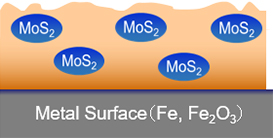

Fig 3. Conceptual rendering of MoDTC films

Use of an additive called molybdenum dithiocarbamate (MoDTC) is very effective for reducing friction between parts. MoDTC reduces friction by forming a film of molybdenum disulfide (MoS2) on the surface of metal parts, but its effectiveness can vary greatly depending on the type of metallic detergents that are also added to the engine oil.

Hoping to reduce friction still further, we turned our attention to metallic detergents and developed one that enhances the friction-reducing effect of MoDTC. This new additive acts to promote MoS2 film formation on metal surfaces, resulting in measurably lower friction coefficients.

We've also shown that aside from improving fuel efficiency and acceleration, reducing friction also reduces noise and vibration in the engine for an overall better driving experience.

In addition to reducing friction and providing outstanding engine protection, our low friction engine oils help prevent a type of abnormal combustion called Low Speed Pre-Ignition (LSPI), a common problem in the smaller turbocharged engines which have become so popular.

Formulated with a high viscosity index base oil and our unique additive technology, we put our best into creating ENEOS X PRIME engine oil.

Development of EAST: ENEOS Ash Softening Technology

Diversification in Marine Cylinder Oils and Marine Fuels

An engine oil serves several functions. Among them, one important role is to protect the engine against corrosion by neutralizing the sulfuric acid that forms through reactions involving sulfur in the fuel. This acid is neutralized by alkaline components (mainly calcium carbonate) contained in additives called metallic detergents. Marine cylinder oils in particular are formulated with higher levels of metallic detergents, because marine engines often run on fuels (heavy oil) with high concentrations of sulfur.

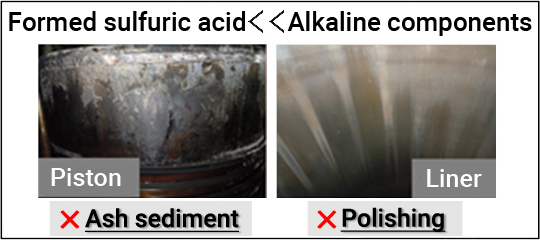

Meanwhile, amid growing concern for protecting the marine environment, restrictions on the sulfur content of fuels have gotten tighter. Currently, there are restrictions on sulfur content for fuels used in open seas, and even stricter restrictions that apply to areas designated as Emission Control Areas (ECAs). Because the upper limits on fuel sulfur concentration differ in open seas and emission control areas, ships carry both high sulfur and low sulfur fuels, and switch between them as the situation dictates. If the marine cylinder oil doesn't contain enough metallic detergents to handle the high sulfur fuel, the sulfuric acid will not be fully neutralized, leading to corrosion and wear to the engine. Conversely, with low sulfur fuels, an excess of metallic detergents in the cylinder oil can lead to formation of hard deposits of ash on the pistons, which are a cause of wear (polishing). This means it is necessary to switch from one cylinder oil to another, each with a different level of acid neutralizing performance, when using fuels with different sulfur concentrations in marine engines.

EAST: ENEOS Ash Softening Technology

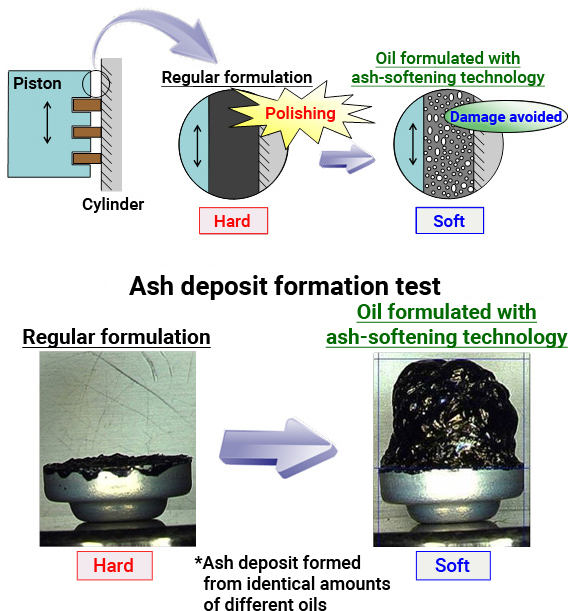

We're working on original technologies that make it possible to use a single type of marine cylinder oil even in ships using both high- and low-sulfur fuels. One such example is JAST (ENEOS Ash Softening Technology). Used in a marine cylinder oil, this technology acts to soften ash deposits, which are normally quite hard. When the ash is soft, it crumbles easily and does not accumulate on the moving pistons, which helps prevent damage from polishing. This ENEOS technology has been proven effective in actual engines and shown to keep pistons clean in long-term operation.