Development of Synthetic Fuel Production Process from CO2 and H2

Synthetic fuels for realizing contribution towards carbon neutralization

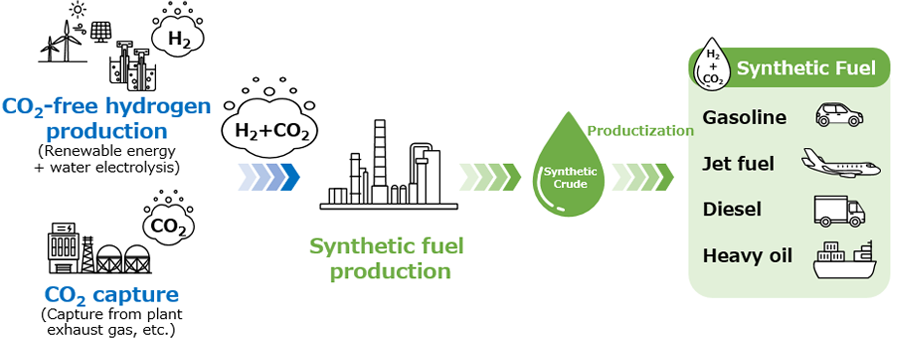

To significantly reduce CO2 emissions in the transport sector including automobiles, aircrafts, and other vehicles toward carbon neutralization, ENEOS is developing Synthetic Fuel production process used "CO2" and "hydrogen" as an alternative to existing petroleum products (gasoline, jet fuel, diesel fuel etc.).

Synthetic fuels produced from "CO2 captured from industrial exhaust gases and/or the atmosphere" and "hydrogen derived from renewable energy sources" can cancel out the amount of CO2 emissions when it is used as fuels and can therefore contribute to carbon neutralization throughout the entire product lifecycle.

Since synthetic fuels consist of components quite close to those of existing petroleum products, it has the advantage of being able to use existing refinery equipment, the fuel distribution infrastructure, automobiles and aircrafts, etc. Consequently, when this technology can be established, it should be possible to quickly spread the use of synthetic fuels in society.

Commercialization for this technology will require a variety of technical innovations such as production process engineering and catalysts technology etc., so ENEOS is participating in the "Green Innovation Fund – Development of Technology for Producing Fuel Using CO2, etc. Project" of Japan's New Energy and Industrial Technology Development Organization (NEDO) and working to establish technology for highly-efficient production process for synthetic fuels.

Catalyst/industrial process developments for producing synthetic fuel with high conversion

Hydrogen and CO2 are produced and/or captured using large amounts of renewable energy, which accounts for the greater part of the production cost for synthetic fuels. To reduce the cost toward the widespread of synthetic fuels, it is vitally important to make these raw materials into products with little waste. When hydrogen and CO2 react, by-products are generated in the form of light gases such as methane other than distillates that become the basis for the product. Consequently, to obtain the product in a more efficient manner, it is necessary to develop a catalyst/production process that can minimize these by-products.

Toward commercialization of synthetic fuel production technology

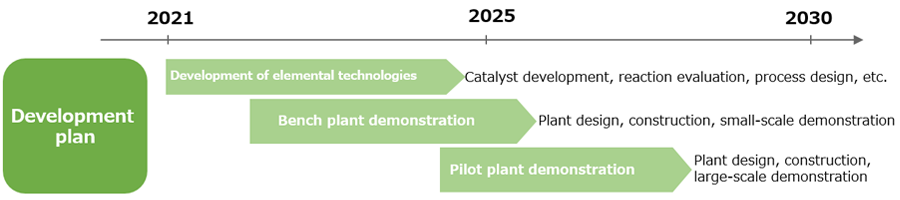

With the aim of achieving commercialization of synthetic fuels, ENEOS is moving forward alongside with a roadmap of Japanese government and is planning scale-up demonstration on a plant level starting after FY2022.

Through these R&D efforts and scale-up demonstrations, ENEOS aims for early establishment of this technology and introduces the environment-friendly synthetic fuel production in the near future.