Using Plastic Waste in Asphalt Pavement

Material Recycling of Plastic Waste

The total amount of plastic waste discharged in Japan has recently reached about 9 million tons annually, of which about 7.5 million tons or more than 80% is said to be recycled in one form or another. One aspect of this effort is that part of the recycling system has a definite effect as in the recycling of PET bottles. The reality, however, is that plastic-waste recycling is dominated by thermal recycling of heat accompanying the incineration of trash as energy recovery used for generating electricity or other purposes. At roughly 5 million tons, this is about two-thirds of the total amount of recycled plastic. On the other hand, the amount of recycled plastic in terms of reusing post-use products (material recycling), which is the most popular image of recycling, is about 1.5 million tons, which is not even 20% of all plastic waste discharged in Japan.

There are a great many types of plastic depending on its application. In addition, different types of plastic are often used in a composite form to combine the features of each. In this case, however, material recycling, which requires those individual materials to be returned to their original forms, is not practical. Thermal recycling can therefore be considered a reasonable method for using the characteristic of “generating heat by incineration” common to such diverse types of plastic waste. Looking to the future, however, there is a need for reusing plastic that reduces this type of incineration-based consumption from the viewpoint of reducing CO2 emissions.

At ENEOS, we have developed road pavement that can directly use the characteristics of "it's a solid" and "it melts by heat" common to plastic waste. In this way, by upgrading recycling from thermal recycling to material recycling, we aim to promote resource circulation.

Asphalt Pavement

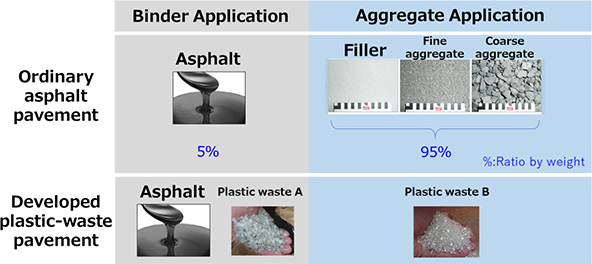

Road pavement is commonly called "asphalt," but the ratio by weight of asphalt to all the materials used in road pavement is only about 5%. Most of the pavement body consists of gravel, sand, and pulverized inorganic matter called filler (Figure 1). This combination of gravel, sand, and filler is called "aggregate." Asphalt plays the role of a "binder" that prevents this aggregate from falling apart.

We are researching a new pavement body not only for the purpose of using plastic waste in modifying the binder but also to use it in the aggregate that up to now has consisted of gravel, sand, etc. Using plastic waste in the aggregate as well will enable the processing of dramatically more plastic waste while holding the possibility of making a great contribution to recycling.

Requirements for Using Plastic Waste in Road Pavement

Using plastic waste as an aggregate requires binder characteristics different from those of ordinary aggregate. Since the surface of plastic is extremely smooth compared to that of gravel or sand, plastic cannot be expected to contribute to deformation resistance through the frictional forces between aggregate materials. It is therefore necessary when using plastic waste as an aggregate to supplement these excellent characteristics possessed in particular by gravel and sand on the binder side. On evaluating the performance of pavement with plastic waste as aggregate using ordinary asphalt (Modified Asphalt Type II) as a binder, it was found that this type of pavement was not usable in practice. In this way, since ordinary asphalt is designed exclusively for gravel and sand, plastic waste cannot be used directly as an aggregate in pavement.

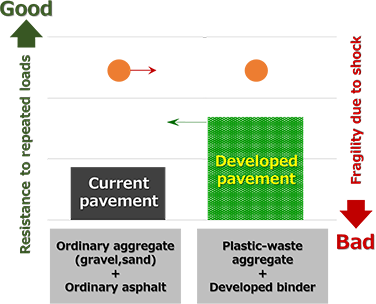

Keeping plastic-waste aggregate stable requires that the binder have adhesive strength with respect to the aggregate while also having the strength to withstand its own deformation. To provide this function, we combined the asphalt with an appropriate type and amount of plastic waste and developed a new plastic-waste/asphalt compound binder that demonstrates sufficient performance even when using plastic waste in the aggregate. As shown in Figure 2, we confirmed that the developed binder could manifest the same level of performance as current pavement using gravel and sand as aggregate even when using plastic waste in the aggregate. At present, we are applying this new developed pavement to a portion of actual sidewalks to conduct a long-term trial of practical performance (Figure 3).

This technology that enables the use of plastic waste in pavement aggregate should make a major contribution to plastic recycling. Moreover, as it can also reduce the weight of pavement by a significant amount, we can also expect it to contribute greatly to alleviating performance requirements in the roadbed materials used to support the pavement and to reducing the amount of energy used in transporting materials. Additionally, since the heat capacity of plastic is small compared with that of gravel and sand, this technology should provide positive effects from various perspectives such as reducing the amount of input heat required during road work and acting as a countermeasure to urban heat islands after paving.