Automotive Drivetrain Lubricants with Fuel-Saving Performance

Automotive driveline lubricants

Climate change is one of the greatest challenges of modern times. Research aimed at reducing the carbon dioxide emissions that cause global warming has been taken up by scientists the world over. Because automobiles are responsible for such a large share of all CO2 emissions, there is an urgent need to improve the energy efficiency of automobiles.

Various technologies for improving energy efficiency are being studied, including those that boost engine performance and others that result in lighter vehicles. But the oils used in automobiles can also have a big effect on energy efficiency. And while hybrid and electric vehicles, which emit little or no CO2, look to become increasingly popular going forward, these will require special lubricants suitable for their particular systems. With all these factors at play, the need for drivetrain lubricants with fuel-saving properties and optimized for specific platforms is stronger than ever.

Continuously variable transmission and transmission fluid

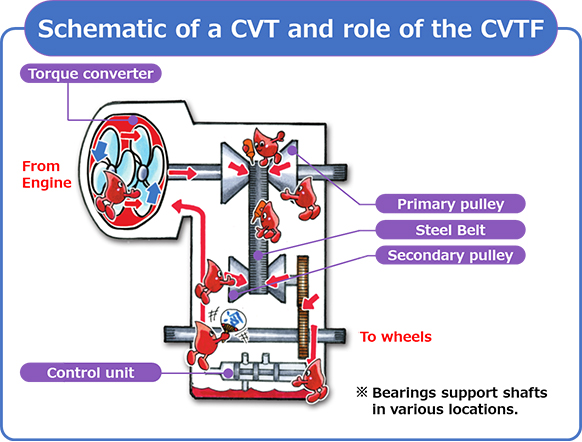

The units that make up a CVT include a torque converter, a metal belt and two pulleys (primary and secondary), and a control unit (hydraulic controller). Torque from the engine goes through the torque converter to the primary pulley, and is then transmitted to the secondary pulley via the metal belt. The gear ratio in a CVT can be varied continuously, using hydraulic pressure to change the width of the gap between the pulley halves. The CVT fluid not only performs a lubricating and cooling function inside the CVT, but also acts as a hydraulic fluid for operating the pulleys.

It must also ensure there is adequate friction to keep the metal belt and the clutch in the torque converter from slipping.

Fuel-Saving Technology

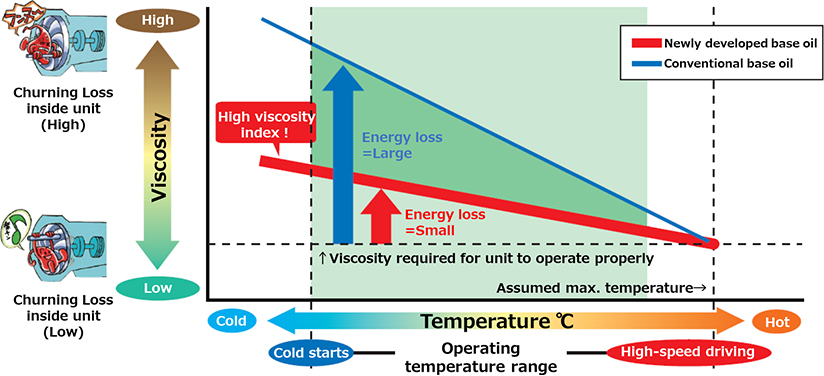

To create a lubricant with low viscosity that still performs reliably, we need to focus on improving the viscosity index (VI), which is an indicator of how much viscosity will be affected by temperature. The higher the viscosity index, the less the viscosity will change with temperature. By raising the viscosity index, we can avoid having the oil be too thick in the operating temperature range, while still ensuring it has sufficient viscosity in the high temperature range. This is aimed at reducing churning loss in the transmission.

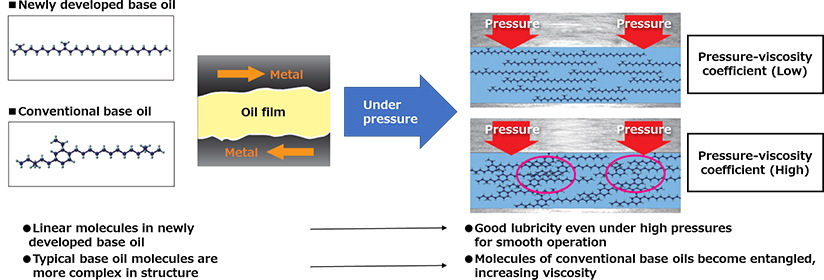

ENEOS developed a synthetic base oil with a low pressure-viscosity coefficient and a viscosity index higher than anything else on the market today. This base oil allows us to formulate oils with both lower viscosities and higher viscosity indices.

- 1.15% higher viscosity index than conventional synthetic base oils

-

The lubricant will not get too thin at high temperatures (e.g. during high speed driving), nor too thick at low temperatures (e.g. during cold starts).

This greatly reduces churning drag and energy losses in the transmission and improves power transmission performance.

- 2.Around 10% lower pressure-viscosity coefficient than regular base oils

-

A lower pressure-viscosity coefficient means that viscosity is less affected by changes in pressure. This means the viscosity of the lubricant will increase less under the high pressures inside the transmission, thus significantly reducing energy losses (viscous drag) and improving power transmission performance.

Gear oil for large vehicles

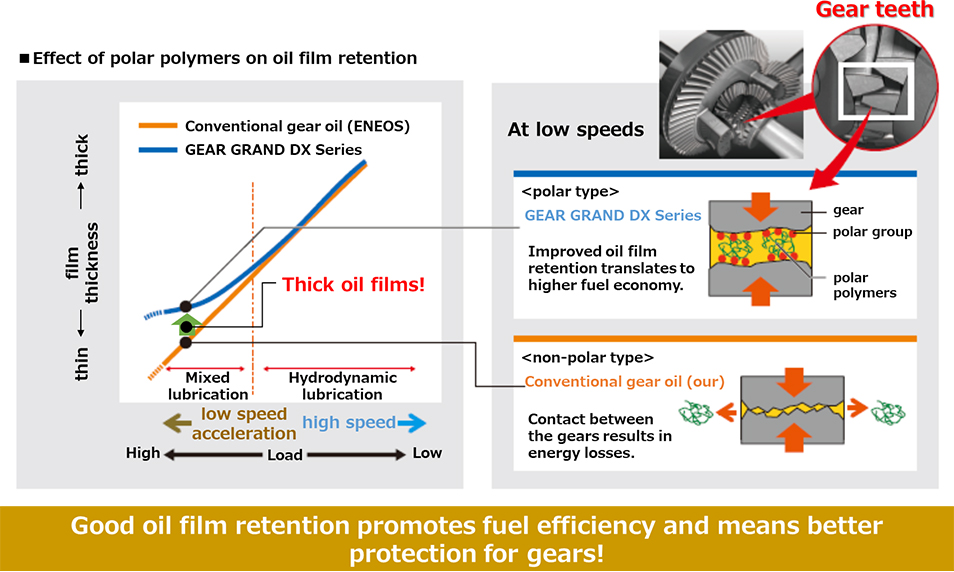

When creating drivetrain lubricants, a common strategy for reducing energy losses due to agitation is to give the oil a low viscosity. But with differential gear oils, lowering the viscosity may mean the oil will not provide sufficient protection to the gears, due to the extreme conditions in which they operate. We thus set out to find a new way to improve efficiency that does not involve lowering the viscosity of the lubricant.

Through a series of studies, we found that a type of highly viscous polymers called polar polymers, whose molecules are electrically unbalanced, form thick oil films even in severe lubrication conditions.

Gear GRAND DX GL-5 90, a differential gear oil developed using polar polymers, was shown to improve fuel economy by 4.5% on average vs. our conventional product. It also meets the API GL-5 specification for gear lubricants, so it can be relied upon to provide sufficient protection for differential gears.

The GEAR GRAND DX GL-5 Series was developed using an all-new approach to improving efficiency. These lubricants are good for the environment and can be used with the same confidence as our other fine products.

Awarded

- 2016 "CHO" MONODZUKURI Innovative Parts and Components Award

- 2020 Minister of the Environment Awards for Climate Action

Lubricants for hybrid and electric vehicles

In many respects, hybrid and electric vehicles are mechanically similar to conventional gasoline-powered vehicles, with a key difference being that the former are equipped with electric motors. These motors will heat up as the vehicle is driven, but problems can arise if they get too hot. The motors can be cooled using water or air, but oil-cooling systems are more effective and much more common. With these, lubricating oil is sprayed directly onto the hot parts of the motor. This means that lubricants for hybrid and electric vehicles must perform a cooling role for the motors in addition to providing lubrication and protection for the moving parts common to all vehicles.

With oil-spray cooling systems, it's been shown that the lubricant needs to have a low viscosity to be most effective. Excellent dielectric properties are also required, since the lubricant will be in direct contact an electrical component, i.e. the motor. Using know-how acquired over decades of work on lubricants for automobiles and numerous other applications, we've created a line of products that more than meet the new requirements for today's modern lubricants. The lubricants in the ENEOS EV FLUID series have been formulated with particular strengths, allowing them to offer the best performance for a range of different usage conditions.

< ENEOS EV FLUID Series >

| 1 | ENEOS EV FLUID Gear Protection |

Formulated to provide extra protection for reduction gears. |

|---|---|---|

| 2 | ENEOS EV FLUID HV AT |

Developed especially for hybrid and electric vehicles with the performance attributes of an automatic transmission fluid. |

| 3 | ENEOS EV FLUID Motor Cool |

A balanced formulation that delivers excellent gear lubrication, motor cooling, and dielectric performance. |

| 4 | ENEOS EV FLUID Energy Saving |

The ultimate in motor cooling performance combined with energy-saving properties. |

| 5 | ENEOS EV FLUID Isolation |

Formulated with the highest level of dielectric performance. |

| 6 | ENEOS EV FLUID Battery Cool |

Coolant developed especially for cooling batteries and electrical components. |

Leveraging proprietary lubricating oil technologies designed to work with the ever-evolving drive systems of hybrid and electric vehicles, we remain committed to developing innovative technologies and useful products and services in our effort to win the trust and satisfaction of the customer.